The new workflow is a robust 3D DEM solution for tackling particle movement design issues. To overcome this difficult design challenge, engineers require DEM, coupled with structural and fluid analysis, to assess the flow behaviour of these granular particles early in the design phase. Interoperable with Ansys' flagship solvers (Fluent and Mechanical), the new workflow, called Ansys Rocky, helps engineers 'design highly reliable products, slash development time and win the race to market'.Īccording to Ansys, nearly 70 per cent of industrial products experience bulk granular material flows, where different-sized particles with complex shapes interact, potentially impacting a product's efficiency or structural integrity. With multi-graphics processing unit (GPU) solver technology, you can simulate the behavior of different shaped and sized particles in many industrial applications.ĮSSS and Ansysare working to improve Discrete Element Modelling (DEM) workflows for quickly analysing and assessing particle movement. Manage the animation of simulation results and create panoramic video reports.Rocky is designed to solve engineering problems.Rocky is uniquely capable to models real particle shapes including any solids, 2D shells, and rigid and flexible fibers. Integration with ANSYS finite element solvers Simple import of 3D CAD geometric models, clear definition of the source data and boundary conditions for the calculation The task of rotation, translational and vibrational movement of equipment elements Calculation and three-dimensional visualization of abrasive wear of surfaces Consideration of the rheology of dry and wet materials A wide range of job granulometric composition Double precision calculations (using the corresponding GPU function) Due to the ability to create realistic particle shapes that behave the same as real particles, taking into account various "flow" conditions in ROCKY, one can simulate the operation of almost any installation.

FIUXY ANSYS 11 SOFTWARE

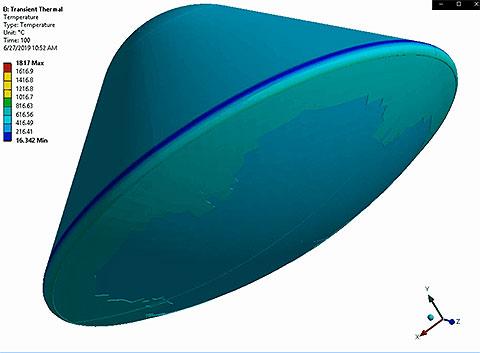

ROCKY differs from other software solutions using the DEM method primarily in the possibilities of using realistic nonspherical particles, simulating their destruction without loss of mass and volume, as well as calculating and visualizing abrasive wear of the working surfaces of equipment elements. With the release of new versions, the capabilities of ROCKY have expanded significantly, and allow you to perform a wider range of tasks, for example, calculating and visualizing the abrasive wear of work surfaces of equipment, calculating air flows arising from the movement of particles of bulk material during transportation, and much more. Initially, the development of the product took place in relation to the tasks of mineral processing, with a focus on calculating the movement of particles in cylindrical mills and continuous transport systems. Further product development will be carried out within the Brazilian company ESSS. The ROCKY software product was created based on 20 years of experience in developing computational techniques using DEM technologies at Granular Dynamics International LLC, a division of Conveyor Dynamics, Inc. The software product uses the Discrete Element Method (DEM), which allows you to quickly and accurately calculate the behavior of a stream of particles of various shapes and sizes when moving along conveyor lines, on vibrating screens, in mills, crushers and other types of processing and transport equipment. ROCKY is a modern software for modeling processes with bulk materials and related equipment. ROCKY is an effective software for modeling granular media by the method of discrete elements (MDE or DEM - Discrete Element Method), allows you to quickly and as realistic as possible to model ix bulk material particles flow with the necessary properties in any process and apparatus.

ESSS Rocky DEM 4.5.0 (圆4) | File size: 689 MB

0 kommentar(er)

0 kommentar(er)